1. Steam heating

The advantage of steam heating is that the heating speed is fast, which is especially suitable for large volume of working tank liquid.

For the heating of working fluid, the metal tube with corrosion resistance and easy heat conduction is used to form a serpentine tube, which is placed at the bottom or side of the tank. Steam is introduced from one end, and the air outlet can be used to heat the hot water tank.There are also rows of tubes for heating. The heating tube is placed at the bottom of thetank, and the heating is more uniform, but it is not conducive to fishing out parts. Therefore, there are many ways to use thetank side heating.

Steam can be directly rushed into the ironing tank for heating, which has high thermal efficiency, but if there is no silencing device, the noise will be large.The working solution such as electroplating solution cannot be directly flushed with steam, otherwise, one is the introduction of many impurities, and the other is the dilution and increasing volume of the solution caused by condensate.

When drying workpieces, there is also a steam oven heated by steam pipe.When the high-pressure steam generated by the high-pressure boiler is sent to the electroplating workshop, the pressure reducing valve should be used to reduce the steam pressure to 0 • 2MPa for steam supply, otherwise the valves, elbows and tees are easy to be damaged.

The alkaline high-temperature bluing solution of iron and steel parts should not be heated with steam, otherwise once the heating pipe embedded in the solution leaks, the bluing solution will burst and splash out.Prone to personal injury accidents.Steam heating has the following disadvantages:

(1) Superheated steam shall be provided by steam boiler.There are many problems in boiler burning, such as: ① softening the boiler water;② Special boiler workers with operation certificates are required to operate;③ The boiler is a pressure vessel, which needs to be shut down every year to clean the scale. The labor law enforcement department shall conduct a routine annual inspection, and can continue to use it only after passing the annual inspection: ④ the boiler is mostly coal-fired (there are also those burning natural gas where there is natural gas), the requirements for the treatment of smoke and dust are higher and higher, and it is difficult to reach the standard;⑤ Regardless of natural gas and coal, the price rises rapidly and the cost is getting higher and higher.The use of boilers has been restricted or prohibited in many cities and suburbs.

(2) It is difficult to realize automatic temperature control.On the one hand, automatic temperature control needs to use high-quality and durable steam solenoid valve to control steam supply and shutdown;On the other hand, the intermittent boiler cannot realize automatic temperature control due to the uninterrupted supply of steam.Therefore, steam heating is rarely used except for the central heating of large electroplating plants or industrial parks in remote places.

2. Circulating hot water heating

The solution that does not require high heating temperature can be heated by hot water circulating through the serpentine heating pipe.Some self-employed households burn small boiling water boilers. When the water in the boiler is burned to 80 ℃ – 90 ℃, the hot water is transported into the heating pipe with a pipeline pump, and the water is returned to the small boiler.For a period of time, the “energy-saving treasure” burning diesel has been applied, which also burns hot water for circulating heating;When the price of diesel rose sharply, the “energy-saving treasure” was eliminated.When heated with circulating hot water, the heating speed is slow.The heating of hot water for high-temperature hot washing is still supplemented by electric heating.

3. Coal furnace direct heating

In order to save money, some township enterprises directly burn coal or natural gas to the chemical cooking tank and alkaline high-temperature bluing tank, and directly heat the tank bottom.There is no much trouble of burning a boiler and it saves money.But coal burning also has the problem of smoke control.It should be noted that the sludge at the bottom of the tank should be cleaned in time.In one factory, the sludge at the bottom of the chemical degreasing tank was too thick, the heat transfer was poor, and it burst suddenly, resulting in the splash of chemical degreasing fluid and serious scalding of operators. The treatment cost was tens of thousands of yuan.

4. Electric heating

Due to many problems and limitations of steam heating, most electroplating plants have switched to electric heating.Electric heating is a kind of clean energy for electroplating plants and will not produce environmental pollution.

Another advantage of electric heating is that it is easy to realize automatic constant temperature control of the solution.

The disadvantage of electric heating is that the heating speed is slow and the electric power is required.For example, for the solution tank without insulation layer, the calculation result is: 1000L solution is heated from 30 ℃ to 55 ℃. If it takes 1h to heat up, the electric power should reach 69kw.When using electric heating, be sure to pay attention to:

(1) In single shift production, constant temperature control facilities must be adopted, and constant temperature and heat preservation shall be adopted in non production.If the bath liquid is stopped and has been cooled to room temperature, it shall be heated in advance at night. When the constant temperature reaches the working liquid temperature, it can work at work. Otherwise, it will be heated at work and it will take a long time to produce.

(2) All working tanks for heating shall be provided with thermal insulation layer.Although the one-time investment is large, the long-term energy-saving effect is obvious. The additional investment of adding insulation layer can be recovered soon, otherwise the gain will not be worth the loss.It also does not meet the policy requirements of “energy conservation and emission reduction”.

During non production or pre heating, the surface of the notch shall be covered tightly with thick plastic cloth.Some people are willing to use their brains. When they don’t produce at night, they cover a quilt on the plastic cloth to prevent heat loss. The effect is obvious and worth learning from.

5. Indirect heating by jacket tank

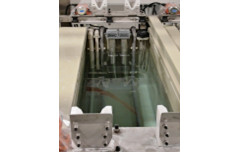

For the solution of corrosive heater (such as fluoroborate tin lead alloy solution) and some solutions that are not allowed to be overheated locally and require uniform heating (such as slightly acidic electroless nickel plating solution) and solutions that need to be heated and cooled (such as electropolishing solution for aluminum parts and size chromium plating solution), sometimes the jacketed tank heating method is still used.Several problems needing attention in jacket tank heating:

(1) Thermal conductivity and anti-corrosion of inner tank

When the jacket tank is heated, an outer tank with sufficient mechanical strength is sleeved at a certain distance outside the inner tank. Water is introduced into the jacket, steam or electric heating is applied to the water in the jacket, and the heat is transferred to the solution through the inner tank.It has large heating area, uniform heating and no local overheating.The selection of materials for the inner tank should be both anti-corrosion and good thermal conductivity.

① Hard chromium plating can be made of industrial pure titanium, which has good effect, but the cost is high.Units with strong financial strength sometimes use.

② Electroless nickel plating can be carried out by carefully passivated stainless steel bath (sometimes with anodic protection) or acid resistant enamel bath.

③ When electropolishing, thin stainless steel or carbon steeltank is lined with lead plate (titaniumtank is not corrosion resistant).

④ Fluoroborate plating tanks are generally small, and thin PVC tanks are used.

(2) Water level between the inner tank and external tank

Considering the heat conduction of the inner tank, the inner tank is thin and the mechanical strength is not enough.However, when the water level between tanks is high enough, the pressure between the solution and the water between tanks is basically in equilibrium, and the force on the inner tank is very small.For this purpose, ensure that the water level between tanks is high enough. In order to supplement the evaporation loss of the water in the jacket layer after heating in time, it is best to set up automatic water level control facilities.In order to easily observe the water level, a water level gauge shall be set at least as the boiler, and the water shall be replenished manually in time.Overflow water outlet is set in the outer casing tank to control the liquid level not to be too high.

(3) Temperature control

Digital display temperature controller is adopted, and the temperature control probe is placed in the working fluid.When jacket water is electrically heated, control the on-off of the power supply of the electric heater.When heated with steam, the steam supply is controlled by the steam solenoid valve.

For electropolishing, hard chromium plating and other processes with rapid temperature rise of plating solution due to high current density in production, they should be heated to the working solution temperature at the beginning, and then cooled by cold water.Cut off the heating source when the working liquid temperature is reached, and the temperature controller is only used for monitoring the liquid temperature;When the steam is heated, close the manual steam valve and fill in cold water instead;During electric heating, cut off the heating power supply and open the cooling water supply valve to supply cooling water.Adjust the cold water supply according to the liquid temperature value displayed by the temperature controller to keep the liquid temperature within the allowable range of the process.The cooling water is used as cleaning water.

Dec. 20, 2019

Dec. 20, 2019