1,Problems existing in aluminum alloy electroplating

The structure of aluminum alloy components is complex and there are many kinds, so there are three problems in the electroplating process.

(1) Easy to fall off. Chemical properties of aluminum is relatively weak, but aluminum and oxygen easily REDOX reaction generates a dense layer of oxide film adsorbed on the surface of metal aluminum, to prevent the further corrosion of aluminum, but the conductive threshold due to the existence of the oxide film in 0.5 V, and the coefficient of expansion of aluminum is larger in many metals, If the oxide film is not treated well before electroplating, it is easy to cause the electroplating layer to fall off.

(2) The coating is prone to porosity, trachoma, cracks and other phenomena. In the electroplating process, electrolyte and hydrogen are easily retained in the pores and trachoma, which have a great influence on the adhesion between the coating and the substrate.

(3) Poor adhesion between coating and substrate. If the oil pollution on the surface of aluminum is not clean or the surface acidification degree is not enough, it will lead to the difficulty of coating, resulting in too thin coating, affecting the binding force between coating and matrix.

Reasons for the problems of aluminum alloy electroplating

For the problems in the above plating process, the reasons for the above phenomena mainly include the following three aspects:

(1) substrate surface is uneven, the internal cavity hole is small, and the hole is deeper, cleaning process before plating is not complete, metal ions adsorption force is very weak here, lead to the perimeter of the empty slot coating is very thin or no coating, this phenomenon is very common in the electroplating phenomenon, because every artifact has its particularity, so before plating must be thoroughly cleaned.

(2) to the requirements of the product’s performance, sometimes will design matrix with tapped hole and blind holes, in accordance with the requirements of electroplating process, the threaded hole and blind holes can’t be plated, but the threaded hole before electroplating and blind hole cleaning, chemical cleaning fluid inevitably into the threaded hole and blind holes, finally rinse rinse clean and it is hard to chemical cleaning fluid, In the later electroplating process, the temperature rises and the gas expands, resulting in the pressure difference, which ultimately leads to no adhesion of the electroplating.

(3) before electroplating, acid and alkali treatment is needed on the surface of the substrate. Acid and alkali solution will corrode the edge of the protective film, resulting in skin warps. If the acid and alkali solution is accidentally infiltrated into the crack when cleaning with acid and alkali solution, and it is difficult to clean with water later, it will eventually affect the quality of the coating.

2,Aluminum alloy electroplating process

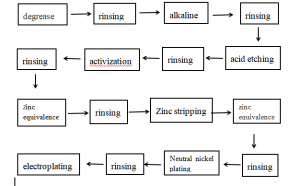

Aluminum alloy electroplating process can be divided into three stages, the first stage is the pretreatment stage, the second stage is electroplating stage, the third stage is electroplating post-treatment stage.

The pre-electroplating treatment stage is the most important part in the whole electroplating process. The quality of pre-electroplating treatment directly affects the quality of electroplating. Before electroplating, grease and oxide on the surface of the substrate are mainly removed, and the electroplating process is as follow:

3, Aluminum alloy electroplating process improvement

In view of the above problems in the electroplating process and the analysis of the causes, we have improved the aluminum alloy electroplating process, mainly from the improvement of the washing way and the use of ultrasonic cleaning.

Water cleaning method improved

In order to improve the cleaning effect of the water cleaning liquid on the Angle and crack of the workpiece, we improved the water refreshing mode. The air stirring place in the water tank before the improvement is normally open, and the workpiece falls into the water cleaning tank and is cleaned for 1 minute.

After improvement, the compressed air will open automatically when the workpiece falls into the water tank. After the workpiece is placed in the water tank and cleaned for 20 seconds, the workpiece will be lifted and dropped again after the bottom part of the hanging device is exposed to the water. This action will be repeated twice.

The cleaning time is still 1 minute. Next, in order to improve the cleaning effect and not pollute the adjacent tank liquid, the spraying method is improved. Before the improvement, when the workpiece falls into the water cleaning tank, the spraying automatically opens. After the improved workpiece out of the cleaning tank, the spray automatically open.

Ultrasonic cleaning:

Ultrasonic cleaner is the use of ultrasonic transmission in water, ultrasonic vibration frequency and water vibration frequency consistent, so as to achieve the purpose of cleaning.

Ultrasonic cleaning equipment has a strong cleaning ability, mainly due to its strong penetration. Ultrasonic cleaning has a strong cleaning effect on the cavity and empty slot of complex workpiece.

4, Conclusion

Aluminum alloy electroplating process is widely used in the manufacture of alloy materials, although there are many problems in the electroplating process, but as long as we grasp the key points in the process and operate in strict accordance with the process requirements, many problems will be solved, so as to improve the quality of aluminum alloy.