Electroplating production line refers to the general name of all electroplating equipment in order to complete the electroplating process of industrial products. The electroplating process must be completed in order. The electroplating production line is also called electroplating assembly line.There are five common electroplating production lines in electroplating enterprises: manual production line, semi-automatic production line, full-automatic production line, plastic electroplating production line and ring production line.The quality of electroplating production line determines the overall production efficiency of electroplating plant.Which of the five electroplating production lines do you prefer?

1. Manual electroplating line

The dynamic electroplating production line is suitable for precious metal electroplating, such as nickel plating, silver plating, gold plating, etc.The manual electroplating production line has flexible design layout and small floor area. It can have 2 to 3 process flows at the same time, which can meet the electroplating process of a variety of parts.

2. Semiautomatic electroplating line

The semi-automatic electroplating production line is suitable for batch production and mass production of precision electronics and hardware, with large output value and good economic benefits.

During the design of the semi-automatic electroplating production line, the running speed of the crane and hook, the number and area of workpieces, the production beat and process parameters have been calculated. Therefore, the product quality is stable, the consistency is good and the output is large.Semi automatic line is the mainstream equipment in the current domestic electroplating production line because of its strong flexibility, high efficiency and production capacity.

3. Automatic electroplating line

The full-automatic electroplating production line is suitable for products with relatively single products and large output. The control system of the full-automatic electroplating production line adopts PLC control , and the determined process flow can be programmed and input into the computer for full-automatic control.

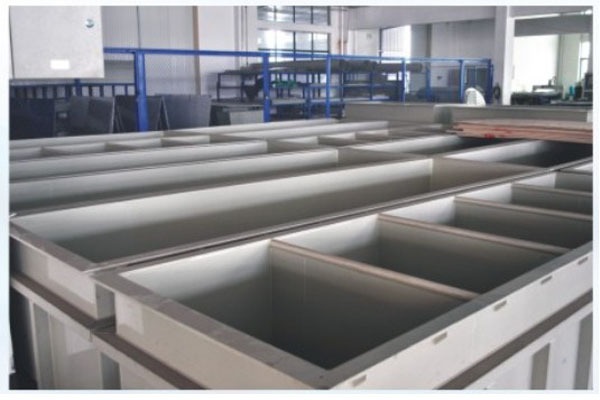

The full-automatic electroplating production line combines the relevant plating tank, plating parts Lifting and conveying device, electrical control device, power supply equipment, filtering equipment, testing instrument, heating and cooling device, air stirring equipment, etc. according to the requirements of a certain electroplating process, and automatically completes the whole process required by the electroplating process through mechanical and electrical devices, with high production efficiency and stable product quality.

4. Plastic electroplating production line

Plastic electroplating is widely used in automotive decorative parts, mobile phone decorative parts, signs and other industries. With the expansion of the application of engineering plastics, the scope of plastic electroplating is also expanding, which is mainly applicable to the electroplating treatment of abspc plastic products.

Metallized plastic overcomes many defects of the plastic itself, and has the characteristics of good solvent resistance, corrosion resistance, wear resistance, light resistance, thermal conductivity, good metal appearance, coating hardness and so on.

5. Ring electroplating line

The ring vertical lifting electroplating line has a wide range of applications. It is mainly used for products with many kinds, small parts, large output and single process, including plastic electroplating to meet the electroplating requirements of nickel chromium, copper plating, ABS copper nickel chromium and so on.

The structure of the annular vertical lifting electroplating line is very different from that of the ordinary electroplating line.The transverse movement and lifting of the workpieces are no longer carried out for a single groove, but the hanger of the whole line and the workpieces act at the same time. The workpieces of a single groove rises, moves transversely and falls into the next groove, and the workpiece of the plating tank and multi-position medicine tank move continuously in the tank without lifting.

Jul. 17, 2020

Jul. 17, 2020